'019 | FTW_SYMT

-

Lead Designer; Project Duration: 4 months

-

“SYMT” stands for the geometry term “symmetry.”

-

“SYMT” is a sustainability thinking developed as backbone for the project. Rethinking the starting point of typical shoe making process paves way for the design direction of FTW_SYMT. By adopting symmetrical die cut pattern upon each component on both feet, the total amount of steel-made molds drop to half; fusing paper pleating technique into the mono-material fabric increases the structural strength and recyclability.

-

The experimental process proposes feasible option in balancing energy cost, craftsmanship and functionality.

-

Brooklyn, USA / 2019 fall

-

Global Footwear Awards 2020 | Designer sneakers | Gold

Global Footwear Awards 2020 | Ethical Manufacturing | Category winner

Core77 Design Awards 2020 | Personal Accessory | Student Notable

IDA International Design Awards 2020 | Fashion-Footwear | Bronze

-

[design brief]

[shoe making process tree]

The process tree investigates typical footwear manufacturing procedure starting from the dirt. Colors in the graph represent different type of materials and are further distinguished by their own chemical properties as marking textures.

-

How can we achieve a more sustainable shoe making process that could potentially increase the chance for footwear as post consumer recycled objects? Especially the upper?

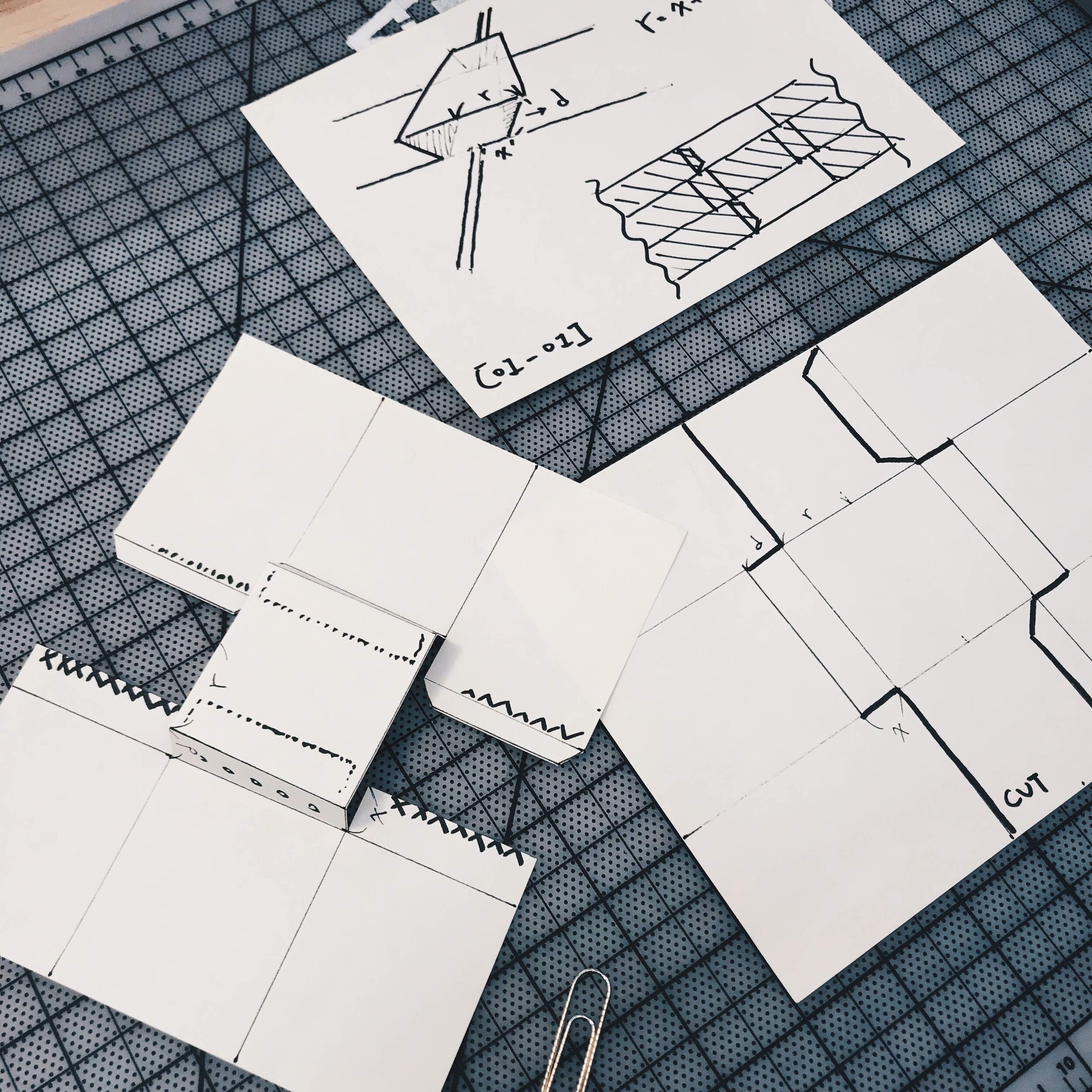

[initializing]

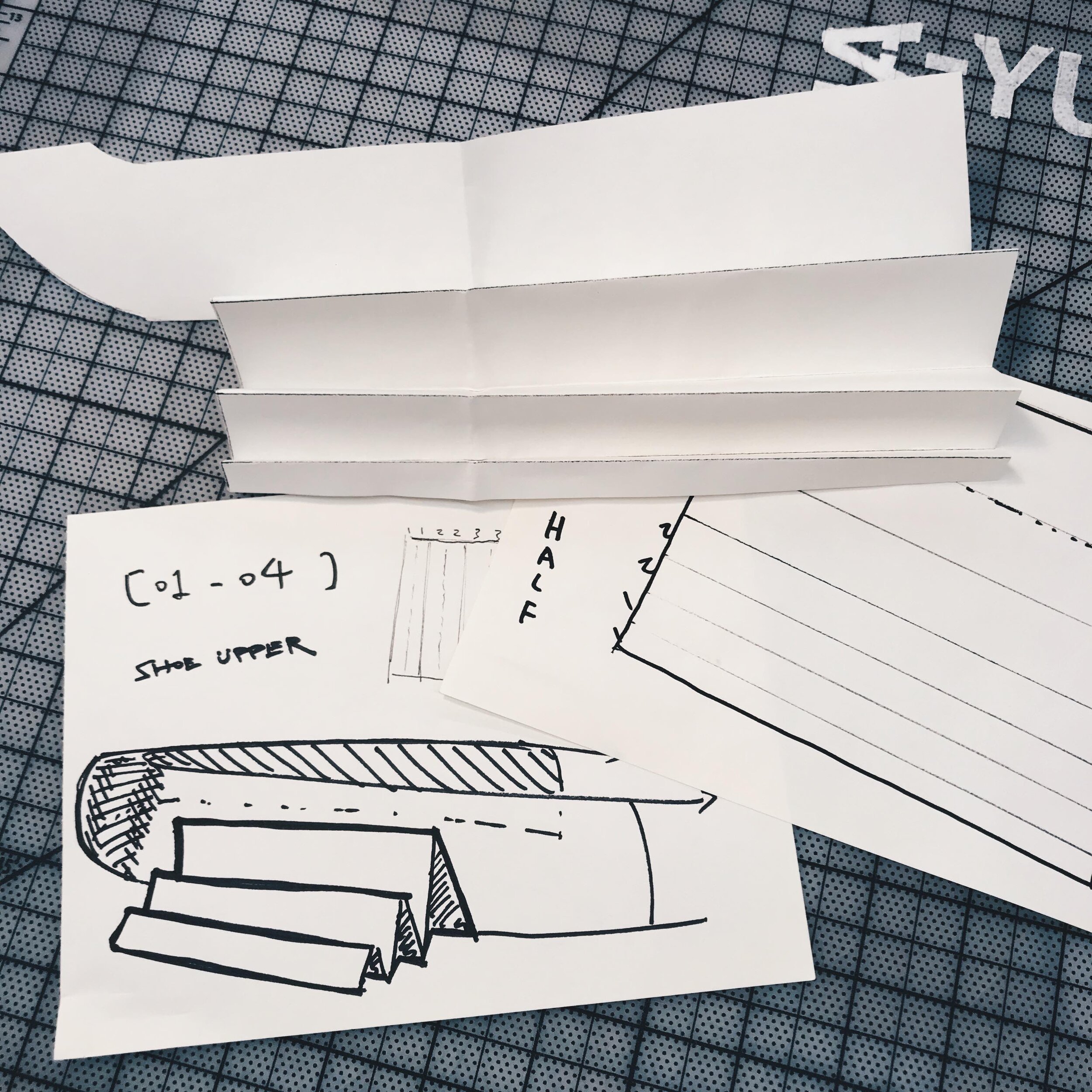

As the sketches forward the concept ideation, the thinking within origami experiments provided the basic logic for the following iterations and expanded the realm of form finding approach.

[paper - canvas transferral]

[M9.5 full scale paper prototype]

[canvas - linen transferral]

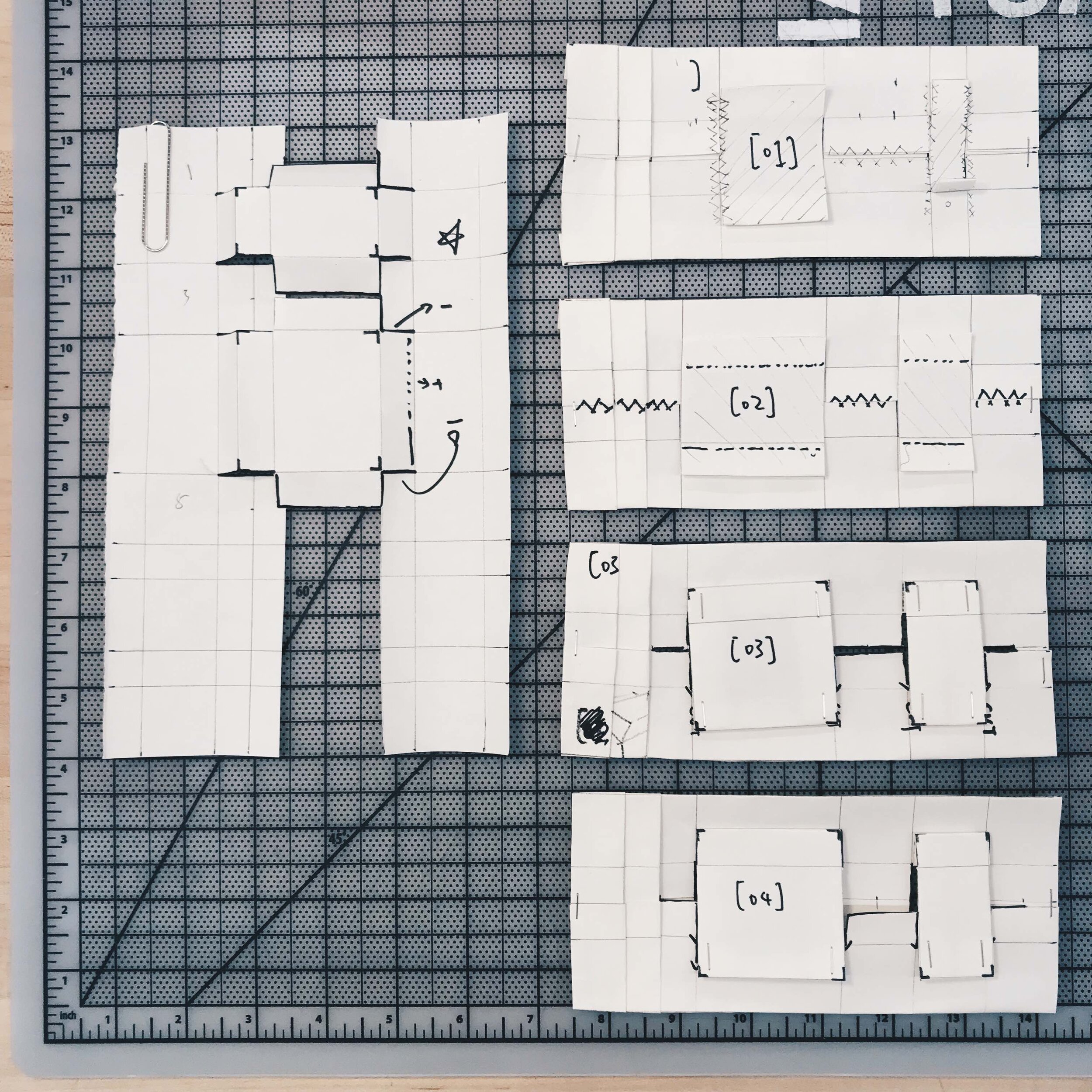

Major advantage of adopting origami fabric is the technique helps creating several shoe components in one single cut fabric, saving time and cost from additional additive or die cut molds; it also embraces the craftsmanship and details.

[embroidery reinforcement]

[assembling ready_01]

[soles transformation]

Fusion 360 - ZBrush

Autodesk Maya

p5.js WebGL

[assembling ready_02]

[outputs]